Please visit the following websites if you are

interested to get more information about landing gears:

1.

Messier-Dowty

2.

BF Goodrich

Chapter 32 Landing Gear

The landing of an

aircraft is usually explained

as no more than an aircraft crash

controlled event.

There are different

landing gear designs. The design and location of the landing gear is

determined by the characteristics of each aircraft, i.e, geometry,

weight.

Weight of the aircraft

in addition to the MTOW (Maximum Take Off Weight) and MLW (Maximum

Landing Weight) are essential factors in the decision in the design of

the landing gear. These

factors determine the number and size of tires, the type of wheels and

brakes, the shock absorber.

When the aircraft

manufacturer is designing the landing gear, they have to obey some

industry and federal standards.

There have been some landing gear changes when a new series in a

model aircraft has been introduced in the market.

The DC 10-10 only had

one nose gear and two main gears as the initial configuration.

The introduction of the later DC 10 model, the DC 10-30, required

the addition of another gear in the configuration of this airplane. The

centerline gear maintains this airplane stable on the ground and aids in

the balance and proper distribution of the increase of the payload on

the Dc 10-30 model. The inclusion of the centerline gear on the DC 10-30

reduced the risk of loading and unloading the wrong way and making it

tail heavy. Some accidents happened during the unloading and loading of

this aircraft.

Another change in gear

design from one model to another was the one done on the Airbus

A300/A310 with the introduction of LaGuardia landing gear design.

Messier-Dowty the manufacturer of the landing gears for the A300/A310

had to develop a landing gear with bigger print for better weight

distribution in order for the New York airport authorities to allow the

airplane to land in La Guardia airport.

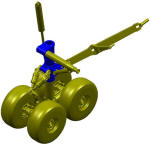

This page also

includes some pictures of the

JetBlue 90 degree landing gear

incident. I

was involved in the inspection and part of the investigation of this

landing gear. After the investigation several recommendations and

modifications were made to the landing gear. One recommendation adopted

was the decrease the number of times the computer check the alignment

(lock in place straight attitude) of the nose landing gear. The computer

was programmed to check the gear lock down position each second. The

computer sent signals to the steering actuator,RVDTs to apply forces to

the shock absorber to ensure the shock absorber was still locked down in

position. Each airline has

different policies for the extension of landing gear during approach. In

the event an airline had as a policy to extend the gears three minutes

before landing that means the computer in the A320 would have applied

forces to the shock absorber 180 times! In the case of the JetBlue

landing gear it was adopted to decrease those checks in flight to reduce

the risk of stress raises (cracks) and to modify the top part of the

absorber of the landing gear to make it idiot proof. This particular

gear was re-assembled incorrectly. I believe it took more than 10

landings before the landing gear failed.

The landing gear did

its job and avoided a fatal event. By the way, the main housing in this

gear is made out of a special aluminum to reduce weight on the aircraft